Slurry Pumps – Product Applications The lined components of the XPA Rubber Slurry Pump are fabricated using Xinhai Rubber. This rubber material has earned international recognition, primarily for its exceptional abrasion resistance. The XPA Rubber Slurry Pump is an ideal solution for transferring corrosive substances. It is suitable for media with a maximum density of 65% (by weight) and a temperature range of 40°C to 70°C. Its key advantages include: smooth operation, energy efficiency, low noise levels, high flow rate and head, low production costs, high operational efficiency, easy maintenance, and a long service life. Application Scope Concentration/Metallurgical Plants: Used for transferring various types of slurries. Sand Processing Plants: Supplies water and mineral sands to a range of classification and dehydration equipment. Coal Preparation Plants: Transports coal slurry. It also supports the classification, screening, and conveyance of heavy medium materials. Ceramic and Glass Plants: Utilized for conveying kaolin and sand, feeding hydrocyclones, and handling wastewater. Steel Plants: Transfers slurry, rust residues, and corrosive liquids. Please inform us in detail if the pump is intended for use in environments where oil or chemical substances are present. Revision Notes Term Precision: Changed "lining parts" to "lined components" for more technical accuracy; "instrument" to "solution" better fits industrial equipment context, avoiding the overly narrow meaning of "instrument". Expression Optimization: "wins international prominence and recognizing" was revised to "has earned international recognition, primarily for" to fix grammatical issues and clarify the core advantage (abrasion resistance) as the reason for recognition. "in the range of 40°C~70°C" was adjusted to "a temperature range of 40°C to 70°C" to conform to standard English numerical range expression. Structure & Clarity: Added em dashes in the title ("Slurry Pumps – Product Applications") for better readability; used bullet points under "Application Scope" and bolded plant types to make the application scenarios more organized and scannable. "dispose effluent" was updated to "handling wastewater" for more natural collocation in English.

Overview

Theory:Centrifugal Pump

Structure:Single-stage Pump

Usage:slurry,mine coal

Power:Electric

Standard or Nonstandard:Standard

Fuel:Diesel

Pressure:standard

Application:slurry,mine coal

slurry pumps certificate:ISO 9001, CE

Centrifugal Pump Price:negotiable

installation:technical guidance

after sale service:the whole using life

warranty:one year

SupplyAbility

SupplyAbility:400 Set/Sets per Month

6/4-MAH Centifugal Slurry Pump With Mechanical Seal

Product Advantages

slurry pumps -Product advantages

1.Smooth operation; less energy consumption; low product cost

2.High flow rate and head; low maintenance

3.Low noise

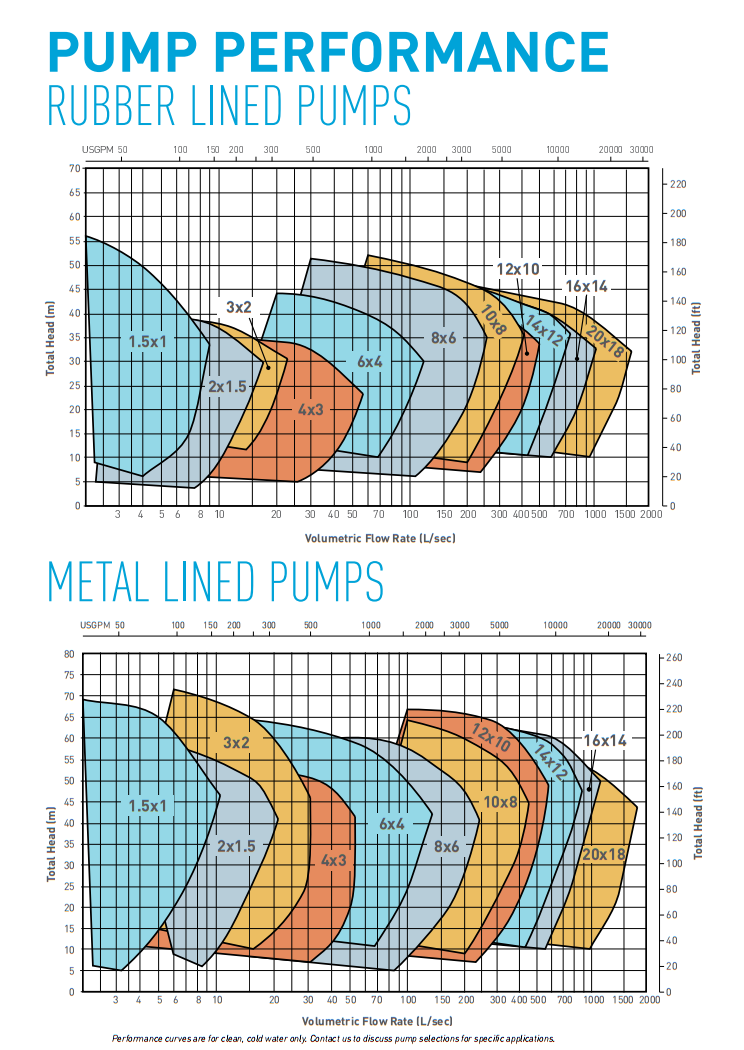

Product curve

slurry pumps - Product feature

XPA rubber slurry pump has features as follows: smooth operation; energy saving; low noise; high flow and head; low production cost; high efficiency; easy maintenance; long service life.

slurry pumps - Product application

The lining parts of XPA rubber slurry pump are made of Xinhai rubber which wins international prominence and recognizing by its extraordinary abrasion resistance. XPA rubber slurry pump is the ideal instrument of conveying corrosive materials whose maximum density is below 65% (by weight) and whose temperature is in the range of 40°C~70°C.

slurry pumps - Product principle

The course of using centrifugal force to increase pressure on conveying medium is also the course of transmitting and transforming energy. With impellers, the pump transforms and transmits mechanical energy produced by motor into pressure energy and kinetic energy for fluid.

The pump consists of shell and impellers which are situated on the main shaft and constitute an integral part with prime mover. Prime mover drives impellers to rotate and then impellers drives fluid to rotate, which increase the kinetic energy and potential energy. The pressurized water process and the water absorption process simultaneously take place. The pressurized water process occurs and consists of three stages: liquid is moved from impeller center to rim by the inertia force; liquid moves off impellers and enters into discharge chamber; liquid is discharged via discharging pipes. When liquid moves from impeller center towards rim, a low pressure area around impeller center is formed. When the vacuum around impeller center is high enough, liquid is absorbed in absorption chamber and sent towards impellers by the pressure of absorption end (the pressure is usually the atmospheric pressure). With the continuous operation of impellers, liquid is continuously absorbed and discharged.

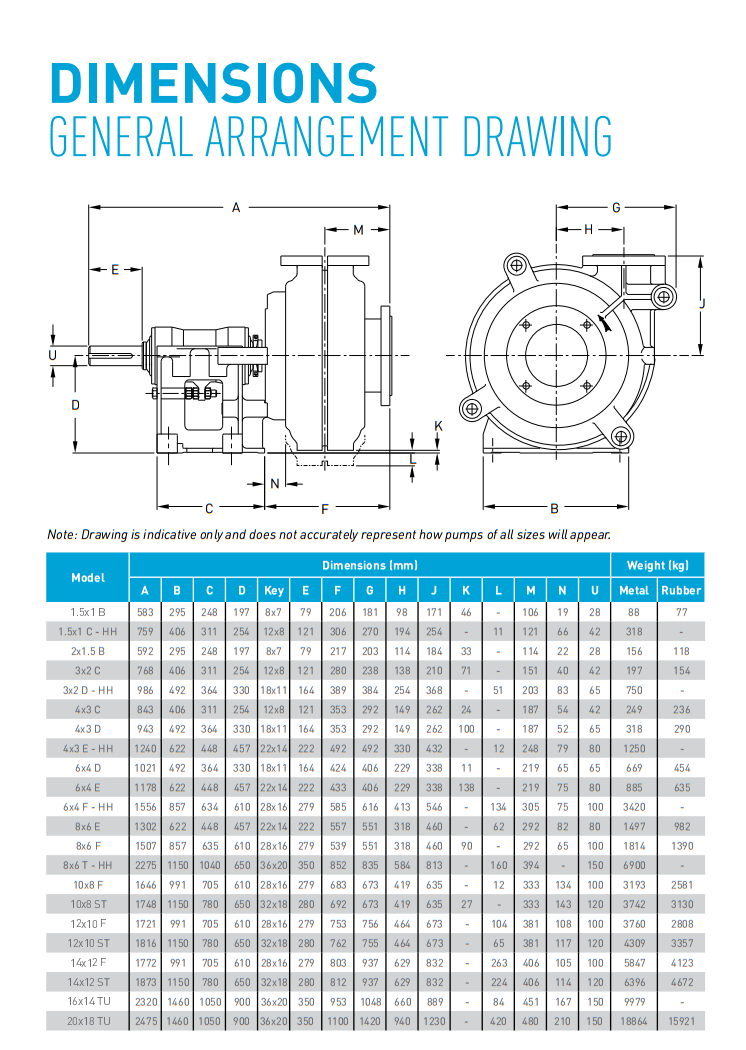

slurry pumps - Dimensions

slurry pumps - materials

Hot Tags: 6/4-mah centifugal slurry pump with mechanical seal, made in China, China, manufacturers, factory, quotation, price list